Wheel loaders are heavily used on the construction site. Being such strong machines with many uses on the jobsite. Not only can they carry and haul things away, but they can clear an area of debris and bring in things like gravel or dirt. While these machines are useful on their own, the addition of innovative technology has improved their ability to help on the job.

Additional support is provided by on-board technology like weighing assistance and smart tires. This technology allows for improved efficiency and productivity as well as simplified operation.

Loading on the Technology

Wheel loaders are an essential part of the jobsite and play a large role when it comes to bringing in and exporting payloads. The machines help load up trucks and help ensure that everything is loaded properly thanks to the skilled operators. But a little help when doing such an important task can be a great relief to operators even if not entirely necessary. With wheel loaders, there are plenty of technologies that have come out and plenty that will continue to come out to make the wheel loader process more efficient and make the operator’s job a little bit easier.  With an on-board tire pressure system, operators and contractors can better maintain fuel efficiency, tire life, operator comfort and machine performance, and save time on routine maintenance.Volvo Construction Equipment

With an on-board tire pressure system, operators and contractors can better maintain fuel efficiency, tire life, operator comfort and machine performance, and save time on routine maintenance.Volvo Construction Equipment

Weighing Assistance

Weighing assistance on wheel loaders takes some of the guessing out of loading. Using a wheel load to fill a truck is made much easier by getting exact weights in each scoop.

“On-board weighing lets you know exactly how much material you are loading, which can reduce or eliminate over- and under-loading,” said Eric Yeomans, product manager — large wheel loaders at Volvo Construction Equipment.

It’s important to know the precise weight of each load and how much each truck is going to carry. If the load is not a good weight, there can be consequences.

Yeomans said, “Overloading can result in costly fines, and under-loading increases production costs. Proper load weight also supports fuel efficiency and helps minimize maintenance costs due to extra wear and tear.”  It’s important to know the precise weight and volume each truck is able to carry.Volvo Construction Equipment

It’s important to know the precise weight and volume each truck is able to carry.Volvo Construction Equipment

Weighing assistance has been around for a while now and can be overlooked because it is not a brand-new innovation but can have more impact than realized.

Yeomans said, “On-board weighing provides … greatly reduce mistakes and increase profits.”

Although weighing assistance isn’t a new concept, there are new things that can come along with it. Weighing scales continue to improve and incorporate more advanced options.

Scott Schmidtgall, product application specialist at Caterpillar said, “They're meant to be on-the-go weighing scales, so the operator doesn't really need to change his operating practice at all. It's meant to complement what he's been doing. It's giving him information about what he's moving and how that machine is performing and what you're doing.”

Rather than taking over the operator’s job, this kind of technology is better at aiding the operator and allowing them to go home at the end of the day less fatigued. Operators are still the experts and are essential on the jobsite. Weighing assistance technologies are for just that - assistance. They are a tool for the operator to use to make their job a little smoother.

“A more precise and confident operator means not only better productivity but also a happier employee,” said Yeomans.

- Collision prevention

- Auto-leveling

- Machine speed limits

- Auto-dig

Tire Pressure Monitoring

Wheel loaders carry a lot of weight and have to roll around, supported by a strong set of tires. On top of having durable tires, it is important to know that the tire pressure is correct. There are different options for this kind of technology available - Volvo has a pressure monitoring system that helps operators easily check the tire pressure from right inside the cab, for example.

Tire pressure monitoring is a useful tool for keeping wheel loaders safe and well-maintained.Volvo Construction Equipment

Tire pressure monitoring is a useful tool for keeping wheel loaders safe and well-maintained.Volvo Construction Equipment

“With real-time information on tire pressure and temperature shown on an in-cab display, they can make sure that tires are operating within the correct parameters. If not, they’ll receive an alert and visual display showing which tire needs attention,” said Yeomans.

Yeomans explained that with an onboarded tire pressure checking system, operators and contractors can better maintain fuel efficiency, tire life, operator comfort, and machine performance, and save time on routine maintenance.

Tire pressure monitoring is a very useful tool for keeping wheel loaders safe and well-maintained. To ensure that such an important part of the machine is in good condition, having a tire pressure monitoring system on board is essential.

Additional Technology and Tips

Wheel loaders are frequently used on the construction jobsite and are seen as a great tool to complete many different tasks on the job. Things like payload weighing, on-board weighing assistance programs, and tire pressure monitoring help by improving accuracy, efficiency, and performance. These technologies help operators and contractors to monitor the performance, accuracy, and efficiency of their jobsite. Other technological applications can work hand in hand with the operators to increase worksite information.

Load Out Monitoring

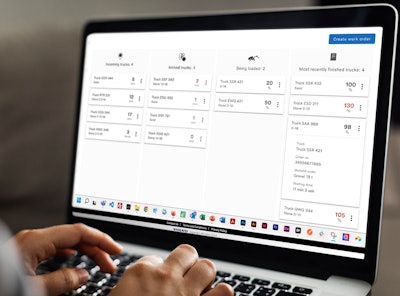

Keeping track of the loads that are being put out on a jobsite can be a huge help on any jobsite. Services like Volvo’s Connected Load Out can provide worksites with a way of monitoring the amounts of each item.

“We … offer a service called Connected Load Out that allows companies to monitor and control the total loads of multiple trucks. A manager can set up a work order with the targeted weights of each material and the names of the trucks, and then monitor and track the material that’s being delivered by each truck,” said Yeomans.  Services like Volvo’s Connected Load Out can provide worksites with a way of monitoring the amounts of each product being loaded.Volvo Construction Equipment

Services like Volvo’s Connected Load Out can provide worksites with a way of monitoring the amounts of each product being loaded.Volvo Construction Equipment

On a construction jobsite, it is crucial to be aware of the exact amounts of each material needed for the job and which trucks are carrying what.

Yeomans said, “They can export data from a flash drive to see every truckload when a particular operator started and finished, what material they took, and so on. This helps them plan ahead and utilize their fleet more efficiently to reduce fuel consumption and emissions.”

Not only can this service help with efficiency and reduction of emissions but it also can help decrease stress levels and time used to work on administration or to travel.

Bucket Size

When optimizing a wheel loader, considering the size of the bucket is a crucial step.

Schmidtgall said, “You want to make sure that you are sizing your bucket and your loader appropriately for the material densities that you're moving. So if you're moving a heavier material like damp sand vs a lighter material density like a clean stone; the heavier damp sand would typically constitute a smaller bucket.”

The size of the bucket can make a huge difference in the productivity of the machine. Taking weight into consideration helps narrow down the most efficient size bucket for the job.

Assistance technology can not only aid the operator, but also reduce fatigue.Caterpillar

Assistance technology can not only aid the operator, but also reduce fatigue.Caterpillar

Some companies offer specially sized buckets depending on the material or application necessary. Finding the correct type of bucket for the material can improve the usefulness of the wheel loader on the jobsite and decrease delays.

“They’re specifically designed for a variety of ground conditions, so operators have an easier time capturing and delivering material — that means faster cycle times and less fuel consumption,” said Yeomans.

Technological Opportunities

While wheel loaders have a few very useful options when it comes to assistive technology, there are a lot more that can help with the everyday work process as well. Depending on what a company needs, many opportunities arise for other beneficial services.  Volvo's Collision Mitigation System helps prevent crashes.Volvo Construction Equipment

Volvo's Collision Mitigation System helps prevent crashes.Volvo Construction Equipment

Other technologies offered include:

These and more are available from various companies to further benefit the operator and worksite team. These kinds of technology are great assistance options to improve overall function and workflow for wheel loaders and workers.

Wheel Loader Assistance

With weighing assistance, payload weighing, and smart tire innovations, wheel loaders have been flourishing in the construction industry. Technologies like these provide the jobsite with simplified operations and increased efficiency. Innovations new and old play a role in the quality of the completed job and the ease with which operators can perform their tasks. This sort of innovative technology is a huge benefit for companies and workers as it can improve useability and accuracy.

Many companies like Caterpillar offer countless on-board technologies used to advance worksite productivity.Caterpillar

Many companies like Caterpillar offer countless on-board technologies used to advance worksite productivity.CaterpillarMany companies like Volvo and Caterpillar offer countless on-board technologies used to advance worksite productivity. Deciding on which innovations to adopt for wheel loaders comes down to personal necessity and goals. Wheel loader assistance is something that has been around for a while. With it, operators can do quality work and still end the day with less fatigue than when they work without assistance tools. Wheel loaders are important powerhouses for the worksite and useful for a variety of jobs. Thanks to weighing assistance, smart tires, and more, wheel loaders keep improving their services and helpfulness in many different settings.