One of the top OSHA recordable incidents on jobsites is struck-by occurrences. There’s a lot of movement on a construction site and workers need to be aware of everything. Rebar, job boxes, tools, equipment, forms, not to mention a litany of construction materials all have to be moved around the site just to do the job. While working nearby, mind your own safety—being aware of the machine is step one. Here is a quick guide for working safely around telehandlers in a concrete construction jobsite.

Situational Awareness

For operators, visibility is vital. Spotters are typically required on the jobsite. Spotters and operators will communicate visually with either a flag or hand signals. Make sure both spotter and operator are on the same page during the morning preconstruction meeting.

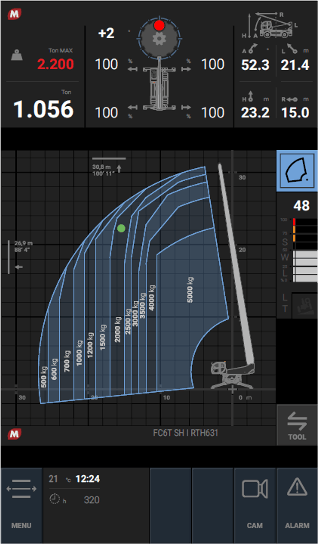

Some telehandlers now include remote control operation, allowing an operator to be their own signal person outside without the potential blind spots inside the cab. Safety-wise, when off the deck with remote control, operators are bringing materials to themselves and being that much more strategic on where to place materials.  Magni America LLC

Magni America LLC

Load & Lift Limits

The average weight is 1,000s of pounds. An overloaded machine or load movement risks a flip-over or drops—not to mention injury to construction workers or damage to the machine and your customer’s property.

Paper charts and load charts are fine, but many modern telehandlers include systems that limit that guesswork. As soon as an operator picks up a load, the system knows how much weight is on the forks, what’s being picked up, the capacity based on how the machine is set up, and if it’s nearing the parameters. The system should not let the operator go past that point notifying the operator with alerts before locking. Manufacturers have either added weight or utilized engineering design and software to increase lifting capacities.

There are also technologies in telehandlers that sense stable ground when applying outriggers.

Certification

Operating a telehandler requires a rough-terrain forklift OSHA 7 certification. Contractors can find a local third-party training company but most telehandler forklift manufacturers/dealer networks offer a train-the-trainer program to provide operator familiarization.

A Clean Jobsite

One of the most proactive ways to affect safety while working around telehandlers is to keep the jobsite clean and clear while holding true to great safety practices. Keeping the ground clear and well-graded will significantly help.

Driving around the jobsite can also produce tripping hazards from the ruts created by the tires. These ruts can freeze in colder climates and become a significant safety issue on the jobsite.

Developed with the assistance of Joseph Leinwol, chief sales officer at Magni America / Magni Telescopic Handlers.