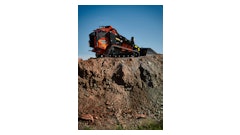

John Deere has launched five new P-Tier Skid Steer Loader (SSL) and Compact Track Loader (CTL) models for construction projects. Entering the market, the 330 and 334 P-Tier SSLs and the 331, 333 and 335 P-Tier CTLs are equipped with a new one-piece cab design, technology features and operating power.

With the introduction of new CTLs and SSLs also comes the debut of three new attachments, including the MK76 and MH72D mulching heads and the CP40G cold planer. Expanding offerings in grade management solutions on compact models, the 333 and 335 P-Tier machines can be equipped with John Deere SmartGrade technology.

“We are beyond excited to introduce the latest John Deere P-Tier compact machines, including the brand-new 334 and 335 P-Tier models,” said Emily Pagura, product marketing manager, John Deere. “Our customers and dealers have been instrumental in driving the development of these new models, and can now experience even more power, technology and innovation on the P-Tier Compact Track Loaders and Skid Steers.”

Cab Design

The new P-Tier models have large, fully redesigned operator stations. Built from the ground up with direct feedback provided by customers, the new models feature multiple styling upgrades. The new operator station is sealed, pressurized and isolated from the frame. This means that outside noise will be lowered and the cab interior is protected from the elements.

Utilizing the 8-in. touchscreen display interface, available on the full line-up of P-Tier models and standard on the 334 and 335 P-Tier, customers can experience insight and customization of machine settings and viewing information. When the premium display is selected, a range of standard features is included within the software.

A new premium heated and ventilated seat supports work in various types of climates.

Aiding operators to focus on the task at hand, hands-free Bluetooth calling capabilities allow the operator to communicate. The pairing of Bluetooth devices is enabled on the touchscreen display and enables the answering of calls and control of streaming audio.

On Board Grade Indicate is standard on the new touchscreen display. This feature displays the cross-slope and main-fall of the machine in either degrees or percent and allows operators to use a relative benchmark to assist in maintaining a desired grade.

Helping with control, the joystick controllers feature adjustable controls that offer personalized setup. The new 25-button SSM puts all functions in one spot, eliminates rocker switches and facilitates machine adjustments while operating.

With a focus on serviceability, the new cab tilts up in one piece, giving ground-level, all around access to the engine, drivetrain and undercarriage of the machine. A single operator or technician can raise the boom and enable mechanical lock out from within the cab. In addition, visibility has increased 20% over the G-Series, improving visibility out the front, sides and back to the machine.

John Deere

John Deere

SmartGrade and Grade Control

Built upon the legacy of the large frame G-Series machines, the new P-Tier machines offer technology capabilities and performance. The 333 and 335 P-Tier Compact Track Loaders can be equipped with SmartGrade Ready including 2D grade control or 3D SmartGrade with Topcon. The machines also include a new hydraulic system.

In addition, On Board Diagnostics enable an operator to navigate through a diagnostic and settings menu structure to look up detailed information on current machine settings and active codes. With the new monitor option, active diagnostic trouble codes will also contain detailed descriptions about the issue and not just the code number.

Technologies and Machine Capabilities

Two brand new technology capabilities make their debut with the rollout of these models, including Attachment Manager and Surround View. Attachment Manager, available as an upgrade on the 330, 331 and 333 P-Tier Machines and standard on the 334 and 335 P-Tier models, takes the guesswork out of determining attachment performance parameters by enabling preprogrammed flow and pressure for John Deere attachments.

From displaying attachment parameters on the screen while running to being able to save or select performance parameters depending on the tool, this new feature helps prevent damage to the attachment related to incorrect machine settings during usage.

Surround View technology, available on all P-Tier models, stitches together views from around the machine to provide a bird's-eye-view image, supporting situational awareness on the jobsite. When reversing, the display will automatically switch to the rearview camera which gives the operator a close view of what’s behind the machine. Surround View dynamically integrates two boom mounted cameras in addition to a rear camera onto a dedicated monitor that provides a 270-degree view of the sides and rear of the machine.

Lastly, the John Deere Operations Center will continue to be included on all large-frame CTL and SSL, enabling fleet managers to monitor machine location, codes, fuel usage and other features.

John Deere

John Deere

Quick-Tatch System Updates and New Attachments

As John Deere rolls out the latest P-Tier CTL and SSL options, it also debuts strategic Quick-Tatch system updates and three new attachment offerings. A full overhaul of the John Deere Quik-Tatch coupler means customers can continue to switch back and forth between attachments. Also, both install implementation and design updates are available.

Entering the market as part of the over 100-attachment offerings available by John Deere, the CP40G Cold Planer and MK76 and MH72D Mulching Heads help expand jobsite capabilities. The CP40G Cold Planer, powered by Wirtgen Group milling machine and cutting technology, provides in-cab controls, including tilt float activation for pass matching across rolling terrain. This rugged model can slide horizontally from left to right, for control, and is designed for pick replacement. Visible indicators for side plate depth, tilt angle and milling drum cut boundary support operation while an optional pressure gauge aids in monitoring milling performance.

Additionally, the optional water tank mounts within the cold planer frame to provide filling and the nozzle kit suppresses dust. In addition, this model is compatible with the 333, 334 and 335 P-Tier machines.

Looking at the latest in mulching attachments, the MK76 and MH72D Mulching Heads are designed to work with the 333, 334 and 335 P-Tier models to take on land clearing needs in stringy, fibrous, dense and fast-growing cycles. Designed to tackle clearing applications, the knife style head on the MK76 is designed for fibrous vegetation. In addition, these mulching head attachments produce the finest chip of all John Deere mulchers, broadcasting discharge to mitigate piles.