Industries like manufacturing and mining have already automated significant portions of their operations, particularly for repetitive tasks. However, the concrete construction sector has lagged for several reasons, including construction sites’ unique and constantly changing working conditions.

How technology is transforming the worksite is a popular topic of discussion. There is widespread agreement that technology enhances productivity by saving time, materials, and resources.

Reality capture, creating detailed digital twins of physical assets, is the lynchpin of the concrete jobsite of the future. It empowers teams to quickly capture and analyze spatial data and provides a deeper understanding of site limitations and obstacles.

To address the persistent labor shortage, attracting younger workers and providing training opportunities for current employees is necessary. Incorporating digital technology into a concrete project will not only extend the lifespan of the asset; it will also align with the trend toward technology-focused job sites.

Using reality capture technologies for BIM modeling, verification, and as-built documentation is a benchmark for predictive maintenance.

A Foundation of Data

Success on the modern jobsite requires intelligence, which relies on constant data collection by workers at every project phase.

Reality capture solutions like laser scanning, mobile mapping, and UAV systems can help a single team member collect site data quickly while minimizing the risk to safety. It also enhances efficiency by organizing the workforce and valuable resources, boosting companies’ profits.

While most business owners prioritize the deployment of technology for its potential to boost productivity and efficiency, it is equally important that these operations contribute to a safer jobsite. Construction executives must ensure that every solution they deploy helps eliminate jobsite mishaps and prioritizes the long-term safety of projects and the teams that make them a reality.

Implementing new technologies may require reconfiguring the value chain, resources, and talent needed for execution. However, with autonomous machinery powered with detailed jobsite data, crews can complete more complex work when they operate.

Decreasing Human Errors

Many concrete construction workers believe technology can help combat the increasing costs of materials, inflation, and the shortage of skilled laborers.

One of the most significant benefits of automation is its ability to greatly reduce the likelihood of human error, which can lead to unforeseen expenses. A smart digital reality helps reduce mistakes and eliminate the unnecessary use of resources.

For example, automation can streamline the collection and reporting of survey data. Inspections are critical to ensure quality and adherence to contracts. Utilizing digital as-builts during these inspections can improve safety and quality and save time and money.

Eliminate the Silos

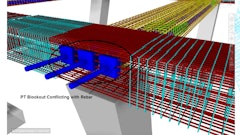

Silos are often created unintentionally through manual processes, and they often limit progress and achievement. Integrating information seamlessly into a system can help eliminate silos and reduce the potential for human error.

For example, a layout specialist working in the field needs access to the design model, and simultaneously the model manager needs data from the field to ensure the model is always updated. But to enable faster and more autonomous field operations, reality capture technology is needed to identify and correct deviations in real time before the concrete is poured or hardens.

A fully autonomous jobsite requires deploying popular and evolving tools that also increase project safety. Teams can use GPS rovers, robotic total stations, concrete detection solutions and laser scanners to capture data, complete calculations, document progress, and confirm quality control.

Reality capture tools allow teams to improve how they track progress, manage schedules and stay on budget while improving the quality of their projects. Autonomy on the jobsite provides peace of mind for everyone, whether in the back-office worker or on the front lines.

By reducing the likelihood of human errors, autonomy enables seamless interaction and ensures that the work teams execute on the jobsite aligns with the project’s plans.

Inspire Confidence

Even before the pandemic, many contractors increased technology adoption and deployment. The use of technology significantly impacts every aspect of the concrete jobsite and leads to critical benefits throughout a project.

BIM Managers and Construction Project Managers should prioritize integrating reality capture technology from the beginning of any construction or renovation project. By addressing potential issues in advance, construction and engineering experts can greatly enhance project efficiency and ensure the timely completion of projects through streamlined workflows, reduced rework, minimized delays, and reduced site visits.

In the construction industry, executives prioritize the practical uses of new technology. They need to protect their resources and ensure that their investments yield returns.

However, it is not wise for any industry or business to adopt technology simply because it is available. Teams should use technology intelligently to simplify and secure jobs and ensure they are completed on budget and according to plan.

Real-time data capture affects every stage of the construction process, including estimating and bidding, construction, project completion, and verification.

Smart digital realities can greatly benefit the industry by providing an accurate digital twin of reality, constantly updated with real-time physical and digital data. This access to valuable insight can save time, reduce waste, and improve safety by eliminating human error.

If technology can keep up with modern industry's ever-changing needs while promoting sustainability, the potential benefits are limitless.