In the high-stakes world of construction, the project schedule is often seen as the immutable roadmap to success. It dictates timelines, resource allocation, and ultimately, profitability. Yet, all too often, this meticulously crafted plan encounters the harsh realities of the jobsite, leading to a phenomenon that can cripple projects: schedule compression.

Simply put, schedule compression is the desperate attempt to complete the same amount of work in a significantly reduced timeframe. It’s the construction equivalent of trying to cram five pounds of sand into a ten-pound bag – a recipe for mess, inefficiency, and ultimately, failure. While the pressure to deliver projects faster is ever-present, the path to achieving true efficiency lies not in frantic acceleration, but in building a solid foundation from the outset.

So, how do general contractors find themselves in this precarious situation? The root cause often lies in the initial project schedule itself. Traditional scheduling methods, frequently reliant on specialized software wielded by a select few, can inadvertently create a disconnect between the planned timeline and the practical realities of the project. These “high priests” of scheduling, while possessing deep technical expertise, may lack the granular, on-the-ground insights from the diverse teams who will actually execute the work.

The consequence of this siloed approach is often an inaccurate and overly optimistic master schedule. It might fail to adequately account for potential delays, resource constraints, or the intricate interdependencies between various trades. As the project progresses, these initial inaccuracies become glaringly apparent, leading to missed milestones and a growing sense of being behind schedule.

This is where the insidious cycle of schedule compression begins. Faced with mounting pressure to recover lost time, project teams resort to reactive measures. Work packages are accelerated, often without a thorough understanding of the downstream impacts. Overtime becomes rampant, leading to fatigue and decreased productivity. Subcontractors are squeezed, potentially compromising quality and fostering adversarial relationships. Materials are rushed, increasing the risk of errors and waste. In this frantic scramble, safety protocols can be overlooked, creating a dangerous environment for workers.

The irony of schedule compression is that it rarely achieves its intended goal. The rushed execution often leads to mistakes, rework, and further delays, pushing the completion date even further out. The increased costs associated with overtime, expedited deliveries, and potential penalties for late completion erode profit margins. Morale on the project team plummets as stress levels soar, impacting collaboration and communication – the very elements needed to navigate complex challenges.

The perils of schedule compression are significant:

- Increased Risk of Accidents: Rushing tasks and cutting corners inevitably leads to a higher likelihood of safety incidents, putting workers at risk and potentially incurring significant costs and reputational damage.

- Diminished Quality: When speed takes precedence over precision, the quality of workmanship suffers. This can lead to costly rework, long-term maintenance issues, and dissatisfied clients.

- Heightened Materials Waste: Hasty procurement and handling of materials can result in damage, loss, and inefficient utilization, driving up project costs.

- Further Schedule Slippage: The reactive measures taken during schedule compression often create a domino effect of new problems, leading to even greater delays.

- Increased Costs: Overtime pay, expedited shipping, rework, and potential penalties for late completion all contribute to significant cost overruns.

- Damaged Relationships: The pressure and stress of schedule compression can strain relationships between the general contractor, subcontractors, and the client, potentially leading to disputes and legal battles.

- Decreased Team Morale: A perpetually stressed and overworked team is a less productive and engaged team. High turnover and difficulty attracting talent can become long-term consequences.

So, how can general contractors avoid this costly and disruptive trap? The most effective strategy is remarkably straightforward: develop a more accurate and realistic project schedule from the outset. This requires a fundamental shift in how schedules are created and managed.

The traditional, siloed approach needs to evolve into a more collaborative and inclusive process. Instead of relying solely on scheduling specialists, general contractors should actively involve a diverse range of project stakeholders in the schedule development process. This includes project managers, superintendents, foremen, and key subcontractors – the individuals with firsthand knowledge of the tasks, durations, and potential challenges involved.

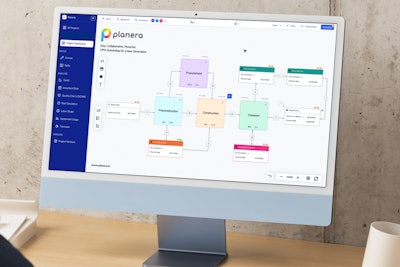

Next-generation construction scheduling solutions are emerging to facilitate this collaborative approach. Platforms like Planera, for example, offer intuitive and visually driven interfaces that make the scheduling process accessible to a broader range of team members. By breaking down the barriers to schedule creation and fostering open communication, these tools empower teams to collectively build a master schedule that reflects a more comprehensive understanding of the project.

The benefits of this inclusive approach are numerous. Schedules developed with input from various perspectives are inherently more realistic and account for a wider range of potential constraints and dependencies. This leads to greater buy-in from the entire project team, as individuals feel ownership over the plan they helped create. Consequently, there is a greater sense of shared responsibility for adhering to the schedule and proactively identifying and addressing potential issues.

Furthermore, these next-generation tools often facilitate the creation of high-quality short-term schedules, a process frequently referred to as pull planning. By collaboratively planning the work for the immediate future, teams can identify and resolve potential bottlenecks proactively, ensuring a smoother flow of work and reducing the likelihood of falling behind. This granular level of planning, informed by the overarching master schedule, provides a crucial layer of control and predictability.

In conclusion, schedule compression is a symptom of a flawed initial planning process. While the allure of a quick fix might be tempting when deadlines loom, the long-term consequences of rushing and cutting corners are invariably detrimental. The path to true efficiency and project success lies in embracing a more collaborative and inclusive approach to schedule development. By leveraging next-generation scheduling solutions and actively engaging the diverse expertise within their teams, general contractors can create more accurate, realistic, and ultimately, more resilient project schedules – avoiding the crushing weight of schedule compression and building a foundation for consistent success.