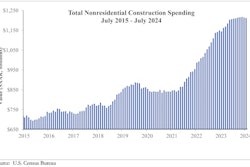

Nonresidential, infrastructure and highway construction jobs continue to rise as communities demand vital road improvements and essential services. According to Richard Branch, chief economist at Dodge Construction Network, highway and bridge construction averaged a 16% increase in jobs, with projected spending of $152.3 billion during this fiscal year. And construction job starts for environmental and public works projects are climbing by 10%.

What does this all mean for contractors? Despite equipment price tag increases, competitive contractors can follow the lessons we’ve learned that maximize efficiency. When contractors learn these lessons and teach them to their team, they can complete more jobs in fewer production hours, equaling less fuel, equipment and labor costs. Consider these five lessons that I learned from jobsite visits with contractors.

1 | Don't Forget: We're in the ‘People’ Business

Broken Arrow’s Cummings and Dennis Howard discuss how he uses his Wingtra Gen II to survey his jobsite in Utah's west desert.RDO Equipment Co.

Broken Arrow’s Cummings and Dennis Howard discuss how he uses his Wingtra Gen II to survey his jobsite in Utah's west desert.RDO Equipment Co.

As the industry brings in more team members, contractors need to create a satisfying work experience and effective onboarding and training. Investing in less experienced operators and growing their expertise will pay dividends in safety and efficiency. Contractors like Hammett Excavation that have developed effective training processes increase their team’s overall likelihood of success. Connected machines through module telematics gateway systems (MTGS) and satellite receivers support recently hired operators by automatically sending data to their team’s fleet manager or a trusted dealer.

Those with decades of experience, like Darin Stroud, Hammett Excavation’s vice president, remember how fleet managers used to have to lean on an operator's ability to self-diagnose issues. Now, Stroud connects as many machines as possible to fleet management software (FMS). Through a MTGS, satellite receivers and an operations management system, operators show their work and discuss improvements with their manager.

Operators can usually access their operations management system through their in-cab display screens and even reach out to remote support from a dealer. When the machine is connected, the operator and the trusted equipment expert can see the machine in real time.

2 | Understand Your Fleet’s Idle Time Reports

Marathon’s Cunningham discusses his idle time reports with RDO Account Manager Ernie Dobson.RDO Equipment Co.

Marathon’s Cunningham discusses his idle time reports with RDO Account Manager Ernie Dobson.RDO Equipment Co.

When managers regularly compare idle time reports over time, they can identify opportunities to boost efficiency by more intelligently managing machines on each jobsite. Fleet managers monitor each machine’s work, which protects equipment investments while creating in-cab resources.

Operators access info about their machine’s performance—including idle time or the current grade—through large display screens. During this high-demand season, contractors can’t afford to miss out on the operations management system’s ability to optimize daily tasks, an exercise that contributes to process, people or project improvements.

3 | Save Time With Machine Control

Machine control technology dramatically improves the production of specific machines. Operators who connect with experienced equipment experts and use machine control get up to speed faster and complete work in less time.

The operator uses an excavator with grade control to complete delicate earthmoving work at the San Dieguito Lagoon project.RDO Equipment Co.

The operator uses an excavator with grade control to complete delicate earthmoving work at the San Dieguito Lagoon project.RDO Equipment Co.

Besides the excavator, contractors say motor graders with grade management or grade control are more accurate for operators at any level of experience. Many dealers offer aftermarket technology upgrades so that contractors can add this type of machine control technology without the price tag of a completely new model.

The in-cab screen displays grade info on the compact machine with grade control technology.RDO Equipment Co.

The in-cab screen displays grade info on the compact machine with grade control technology.RDO Equipment Co.

4 | Constantly Survey Project Progress

Earlier this summer, agriculture and construction machines’ GPS technology was knocked entirely offline during one of the decade’s most intense solar flare storms. Those contractors who invested in MTGS and receiver redundancies prevented downtime. However, those with regularly scheduled progress checks proactively addressed project delays.

This is only one of many recent examples that show why keeping a close eye on every jobsite through automated data collection and daily progress meetings prevented significant and potentially expensive errors (we all know that eliminating rework improves contractors’ resource management). We will look at one way a contractor monitors progress: regularly surveying jobsites to collect data.

Wingtra's ability to survey, record and send data to the FMS helps managers see their progress.RDO Equipment Co.

Wingtra's ability to survey, record and send data to the FMS helps managers see their progress.RDO Equipment Co.

Before the Wingtra drone, keeping a close eye on clay’s processing and accurate grade before harvesting required more machine hours and manpower. Now, with the drone, he relies on near-instant data to harvest at the right time and reduce any possible material loss. Customers like the landfill managers who receive clay from Broken Arrow are confident in the product their team delivers and receive fast and precise clay volume costs.

After collecting this survey data, contractors like Cummings can create 2D or 3D models through computer-aided-design software. With these models, contractors see a real-time view of their projects and game out situations to understand how many machines may be required to complete the job on schedule and budget.

Some equipment dealers can offer 2D or 3D modeling services, so contractors still developing these skills can partner to learn. Contractors who partner with their project managers, surveyors and expert dealers keep projects on schedule despite environmental or technological challenges.

5 | Leverage Jobsite Data to Bid Competitively

This complex earthmoving project required Marathon’s team to move more than 1 million yards of dirt to restore 50 acres of tidal wetland and 15 acres of brackish marsh to create approximately 5 acres of plant life along a man-made river.RDO Equipment Co.

This complex earthmoving project required Marathon’s team to move more than 1 million yards of dirt to restore 50 acres of tidal wetland and 15 acres of brackish marsh to create approximately 5 acres of plant life along a man-made river.RDO Equipment Co.

“This telematics data gives me actual fuel consumption rates for each machine. So, I can figure out how many hours I need for that machine and calculate exact costs,” said Dave Cunningham, chief estimator at Marathon Construction Corporation.

Armed with more data, an estimator can more intelligently bid on jobs. The more you continually learn about your team, equipment and technology capabilities to complete jobs, the more accurate job costs will be in future bids. Cunningham said that this invaluable knowledge informs his bidding strategy, and other estimators should attempt to bid on as many projects as possible to understand their team’s definitive strengths.

Those in the industry continue to predict strong demand for projects well into the latter half of 2025. During changes in demand and high construction costs, contractors and their teams need to determine how they can maximize efficiency without significant time or labor investments. While we cannot control multiple market forces, we can follow these lessons to finish jobs faster.